Zinc Technology: Complete Guide to Applications and Benefits

Understanding zinc technology

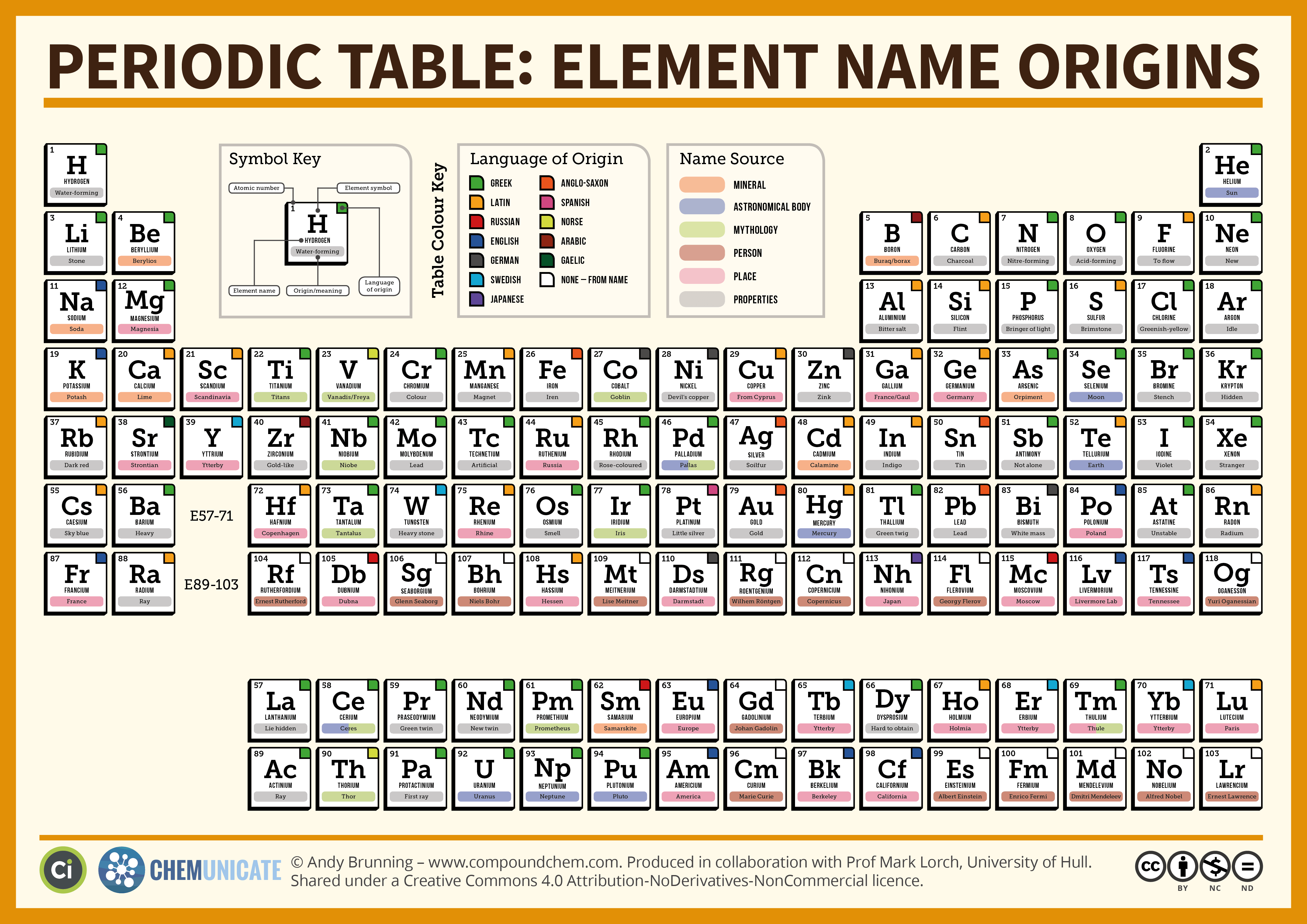

Zinc technology encompass the diverse applications and innovative uses of zinc, a versatile metallic element that play crucial roles across multiple industries. This bluish white metal has evolved from simple galvanizing applications to sophisticated technological solutions that power modern electronics, protect infrastructure, and advance medical treatments.

Source: zink.com

The fundamental properties of zinc make it invaluable in technology applications. Its excellent corrosion resistance, electrical conductivity, and biocompatibility have open doors to breakthrough innovations. Engineers and scientists continue to discover new ways to harness zinc’s unique characteristics for solve complex technological challenges.

Core properties driving zinc technology

Zinc’s technological applications stem from its remarkable physical and chemical properties. The metal exhibit exceptional corrosion resistance when expose to atmospheric conditions, form a protective oxide layer that prevent further degradation. This self-heal characteristic make zinc ideal for protective coatings and long term applications.

The electrical conductivity of zinc, while not ampere high as copper or silver, provide sufficient performance for specific electronic applications. Its ability to conduct electricity dependably under various environmental conditions has lead to specialized uses in batteries, electronic components, and conductive coatings.

Zinc’s biocompatibility represent another crucial property drive technological innovation. The human body course contain zinc as an essential trace element, make zinc base technologies suitable for medical applications and consumer products that come into direct contact with skin.

Electronics and battery technology

Modern electronics rely heavy on zinc technology, especially in battery applications. Zinc carbon batteries have power portable devices for decades, offer reliable energy storage at competitive costs. These batteries utilize zinc as the anode material, where oxidation reactions generate electrical current.

Recent developments in zinc air battery technology promise revolutionary changes in energy storage. These advanced batteries use atmospheric oxygen as the cathode, achieve energy densities comparable to lithium-ion systems while maintain environmental safety. The zinc air configuration eliminates the need for expensive cathode materials, reduce overall battery costs.

Rechargeable zinc batteries represent the next frontier in energy storage technology. Researchers have overcome traditional challenges with zinc dendrite formation and electrolyte stability, create rechargeable systems that offer superior safety profiles compare to lithium base alternatives. These batteries show particular promise for grid scale energy storage applications.

Printed electronics benefit importantly from zinc base conductive inks and materials. Zinc oxide nanoparticles enable the creation of transparent conductive films use in touchscreens, solar cells, and flexible displays. The solution processable nature of zinc compounds allow for low temperature manufacturing processes compatible with plastic substrates.

Protective coatings and galvanization

Galvanization technology represent one of the well-nigh established applications of zinc technology. The process involve apply zinc coatings to steel and iron surfaces, provide sacrificial protection that prevent rust and corrosion. Hot dip galvanizing create thick, durable coatings suitable for outdoor infrastructure and construction applications.

Electroplate with zinc offer precise control over coat thickness and appearance. This technology enable the protection of intricate parts and components while maintain dimensional accuracy. Zinc electroplating find extensive use in automotive, aerospace, and electronics industries where corrosion protection must be balance with other performance requirements.

Zinc rich paints and primers provide corrosion protection for structures that can not undergo traditional galvanizing processes. These coatings contain high concentrations of zinc particles that provide cathodic protection similar to galvanized coatings. The technology prove specially valuable for maintenance and repair applications on exist infrastructure.

Thermal spray zinc coatings offer solutions for large structures and field applications. This technology use specialized equipment to apply molten zinc particles to prepared surfaces, create protective layers that can be applied on site. Bridge maintenance, marine structures, and industrial facilities benefit from this flexible application method.

Medical and healthcare applications

Zinc technology play progressively important roles in medical and healthcare applications. Zinc oxide nanoparticles demonstrate antimicrobial properties that make them valuable for medical device coatings and wound care products. These nanoparticles can eliminate bacteria and fungi while remain safe for human tissue contact.

Bioabsorbable zinc alloys represent breakthrough materials for temporary medical implants. Unlike permanent implants make from titanium or stainless steel, zinc base implants gradually dissolve in the body after serve their therapeutic purpose. This technology eliminate the need for secondary surgeries to remove implants while provide adequate mechanical support during healing.

Zinc base drug delivery systems utilize the metal’s biocompatibility and control dissolution properties. Researchers have developed zinc contain nanoparticles that can deliver medications to specific body locations while minimize side effects. The natural presence of zinc in the human body reduce concerns about long term bioaccumulation.

Diagnostic imaging benefits from zinc contrast agents that provide enhance visibility during medical scans. These agents offer alternatives to traditional contrast materials while leverage zinc’s natural biological pathways for elimination from the body.

Environmental and sustainability aspects

Zinc technology contribute importantly to environmental sustainability through its recallability and low environmental impact. Zinc can be recycled indefinitely without lose its essential properties, make it one of thewell-nighh sustainable metals available. The recycling processrequirese importantly less energy compare to primary zinc production.

Photocatalytic zinc oxide technology offer solutions for air and water purification. When expose to ultraviolet light, zinc oxide generate reactive oxygen species that break down organic pollutants and eliminate harmful microorganisms. This technology find applications in self clean surfaces, air purification systems, and water treatment facilities.

Zinc base materials contribute to energy efficiency in buildings through their thermal properties and durability. Zinc roofing and clad systems provide excellent weather resistance while require minimal maintenance over their extended service lives. The material’s ability to develop natural patina eliminates the need for periodic painting or surface treatments.

Agricultural applications of zinc technology support sustainable farming practices. Zinc fertilizers and soil amendments address zinc deficiency in crops while improve overall plant health and yield. Control release zinc formulations reduce environmental runoff while ensure adequate nutrient availability for grow plants.

Advanced manufacturing and 3d printing

Additive manufacture technologies progressively incorporate zinc base materials for specialized applications. Zinc alloy suitable for 3d printing offer unique combinations of properties include biodegradability, antimicrobial activity, and ease of processing. These materials enable the production of complex geometries that would be difficult to achieve through traditional manufacturing methods.

Zinc die-cast technology continue to evolve with improve alloy formulations and processing techniques. Modern zinc alloys provide enhanced strength, corrosion resistance, and dimensional stability while maintain excelleca stabilityity. The technology support high volume production of precision components for automotive, electronics, and consumer goods industries.

Powder metallurgy applications utilize zinc powders for creating specialized components and coatings. The technology enable the production of parts with control porosity, specific surface textures, and tailor mechanical properties. Zinc powder technology find applications in self lubricate bearings, filters, and decorative coatings.

Future innovations and emerging applications

Quantum dot technology represent an exciting frontier for zinc base materials. Zinc selenite and zinc sulfide quantum dots exhibit unique optical properties that make them valuable for advanced display technologies, biological imaging, and photovoltaic applications. These nanoscale materials can be engineered to emit specific colors of light with high efficiency and stability.

Flexible electronics benefit from zinc base transparent conductive materials that maintain conductivity under mechanical stress. Researchers are developed zinc oxide thin films and nanostructures that can withstand repeat bending and stretch while maintain electrical performance. This technology enable the creation of foldable displays, wearable sensors, and conformable electronic devices.

Energy harvesting applications utilize zinc’s piezoelectric properties for convert mechanical energy into electrical power. Zinc oxide nanowires and thin films can generate electricity from vibrations, pressure changes, and mechanical deformation. This technology show promise for power small electronic devices and sensors without external power sources.

Smart materials incorporate zinc compounds respond to environmental changes such as temperature, pH, or light exposure. These materials can change their properties on demand, enable applications in adaptive coatings, responsive textiles, and intelligent packaging systems.

Industrial processing and quality control

Quality control in zinc technology rely on advanced analytical techniques and testing methods. X-ray fluorescence spectroscopy, scan electron microscopy, and electrochemical testing ensure zinc coatings and products meet specify performance standards. These analytical tools enable manufacturers to optimize processing parameters and maintain consistent product quality.

Automated zinc application systems improve efficiency and consistency in industrial coating operations. Robotic systems can exactly control coating thickness, coverage patterns, and processing conditions while reduce material waste and environmental emissions. These technologies support high volume production while maintain strict quality standards.

Process monitoring technologies utilize real time sensors and data analytics to optimize zinc processing operations. Temperature, chemical composition, and coat thickness can be unceasingly monitor and adjust to maintain optimal processing conditions. This technology reduce defects, improve yield, and minimize resource consumption.

Market applications and industry integration

The automotive industry represent one of the largest consumers of zinc technology, utilize galvanized steel for body panels, chassis components, and fasteners. Advanced high strength zinc coat steels provide weight reduction opportunities while maintain structural integrity and corrosion resistance. The technology support automotive manufacturers’ goals for improved fuel efficiency and extended vehicle life.

Source: zink.com

Construction and infrastructure applications continue drive demand for zinc technology. Galvanized structural steel, zinc roofing systems, and protective coatings provide long term durability for buildings, bridges, and industrial facilities. The technologies prove performance record and cost-effectiveness make it a preferred choice for demand construction applications.

Consumer electronics progressively rely on zinc technology for component protection, electromagnetic shielding, and battery applications. The miniaturization of electronic devices creates new challenges that zinc base solutions can address through their unique combination of properties and processing capabilities.

Zinc technology continue to evolve through ongoing research and development efforts focus on improve performance, reduce costs, and expand application possibilities. The versatility of zinc and its compounds ensure continued relevance in address future technological challenges across diverse industries and applications.

MORE FROM lowcostbotox.com